Air Treatment & Ventilation Units

MAINTAINING AIR QUALITY

Air Treatment : Air treatment in itself has two primary components a) Cleaning of air and b) Evaporative Cooling.

Different applications require different degrees of air cleaning effectiveness. In industrial applications, removing only the larger dust particles from the airstream may be necessary for cleanliness of the structure, protection of mechanical equipment and employee health and in some cases prevention of surface discolouration, in which case the smaller components of atmospheric dust are the worst offenders. Electronic air cleaners or medium to high efficiency dry filters are required to remove smaller particles, especially the respirable fraction, which often must be controlled for health reasons.

In clean room applications or when radioactive or other dangerous particles are present, high or very high efficiency filters need to be deployed.

Evaporative Cooling on the other hand is energy-efficient, environmentally benign, and cost-effective in many applications, ranging from comfort cooling in residential, agricultural, commercial and institutional buildings, to industrial applications for spot cooling in mills, foundries, power plants, and other hot environments.

Ventilation : Depending on the demand and load conditions optimal rates of ventilation need to be maintained so as to keep the toxic gas levels (typically CO, CO and NO ) within prescribed 2 X limits. Various building codes define these limits.

A good ventilation control system not only helps maintain the desired air quality but also saves energy by reducing ventilation rates during low demand,

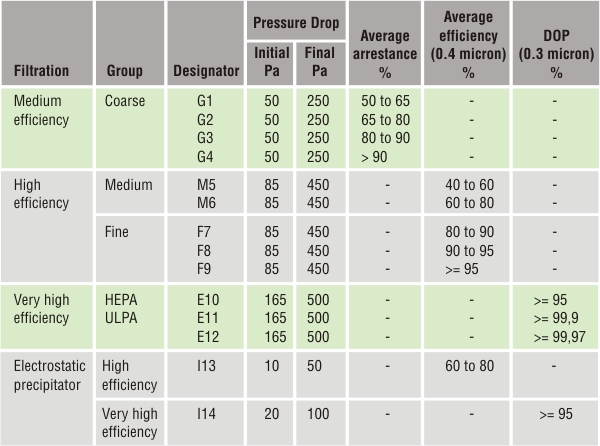

CLASSIFICATION OF FILTERS

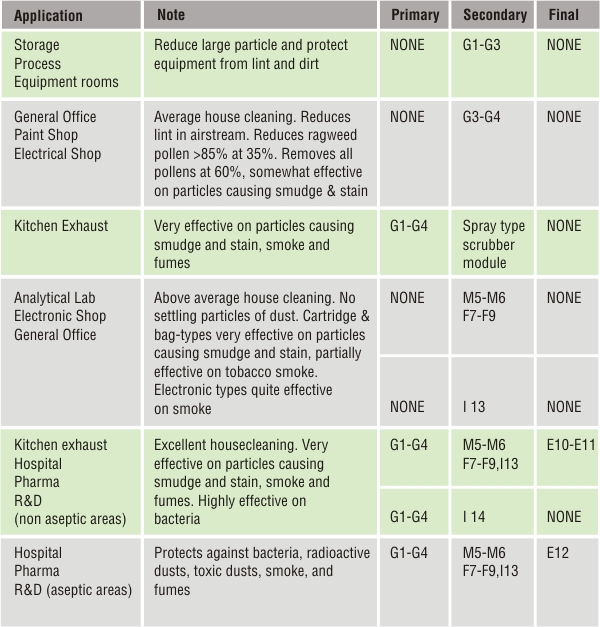

TYPICAL FILTER APPLICATION FOR AIR TREATMENT

CAR PARK VENTILATION

As a rule, car park ventilation is based on 12ACH for normal ventilation and 30 ACH for smoke exhaust, according to NBC India, whereas as per various building codes ventilation is based on 6ACH for normal ventilation and 10ACH for smoke exhaust.

Traditionally CO is considered to be the biggest threat in car parks, followed by NOx where there are heavy loads of diesel vehicles. CO levels should ideally be be maintained within 29 (25) mg/m^3 (ppm), with peak levels not to exceed 137 (115) mg/m^3 (ppm), according to NBC India. Whereas NO levels should be maintained within 1 ppm, as per various building codes.

Since CO2 is always the main product during combustion in presence of oxygen, it provides a good 2 measure of accumulated exhaust and air quality. It also can also be measured more precisely and reliably than any other toxic gas.

With rapid development of environment friendly modern cars that with catalytic converters generate 100-900 times CO2 , as much CO. Therefore CO2 itself is a greater threat to safety and health of the people present in car park.

Coverage of sensor

a. Maximum distance of any corner in the car park to the nearest sensor shall be less than 25m.

b. First 12m from fresh air opening are considered as natural ventilation (NV) zone.

c. Sensors are grouped according to the zones by the exhaust fans.It shall be located at 0.9m ~ 1.8m above floor level. However, for practical reasons (in order to avoid vandalism), the sensors can be installed just above 1.8m.

N = A x SQRT(L/W) / 1000

Where,

N : no. of sensing points

A : Area of car park in square meters

L : Length of car park in meters

W : Width of car park in meters

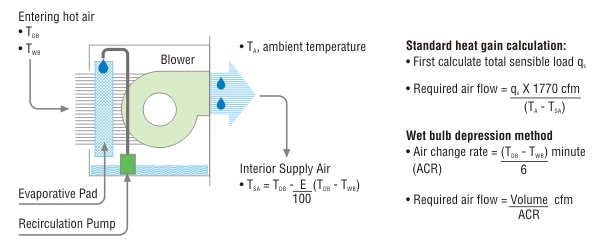

DETERMINING AIR COOLER CAPACITY

The maximum reduction in dry-bulb temperature is the difference between the entering air dry- and wet-bulb temperatures. If the air is cooled to the wet-bulb temperature, it becomes saturated and the process would be 100% effective.

Evaporative coolers are available with 85-95% efficiency.

browse products